2023 Natural Granite Marble Kerbstone Cutting Machine

Description

Basic Info

| Model NO. | DF1200 |

| Cutting Ability | High Speed |

| Control | Artificial |

| Certification | ISO, CE |

| Transport Package | Wrapped with Bubble Plastic |

| Specification | 5500*2800*2500mm |

| Trademark | DAFON |

| Origin | Fujian, China |

| HS Code | 8464101000 |

| Production Capacity | 100 Unit Per Year |

Product Description

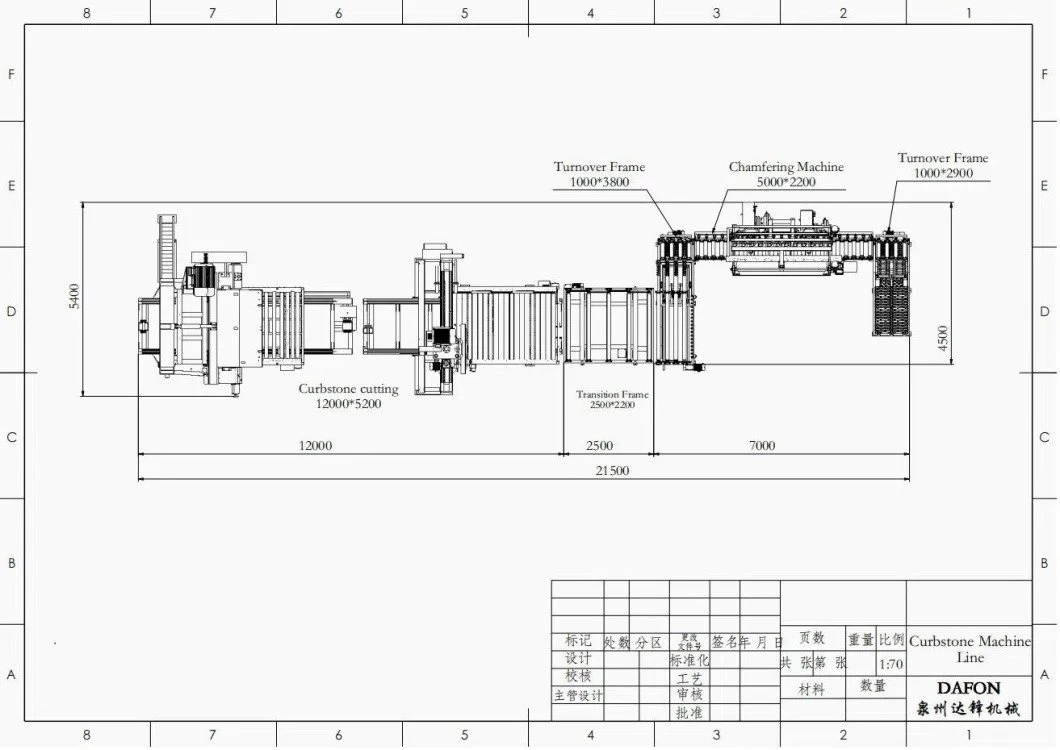

Stone Slicing Machine DF1200-12S: (especially for curbstone)

Features:

1. This equipment proves most effective when used together with stone edge cutting machine.

2. Technical data for long stone cutting:

max. diameter of blade-1200mm;

max. number of blades used-12pcs;

max. Cutting height-450mm.

3. Cast iron is adopted in main frame of the machine to make the machine more stable with less chance of vibration under the operating condition.

4. The machine operates automatically through the main control unit consisting of frequency converter, transformer, AC contactor and time relay, which can more effectively control vertical movement of oil cylinder, trolley operation and slab cutting efficiency.

5. Unlike traditional stone cutting, it dramatically increases the productivity and reduce labor cost and power consumption and it consumes less diamond segment per cubic meter of production compared to the traditional cutting machine.

Technical Data:

| Dimension (mm) | 6000*2800*2500 |

| diameter of blade (mm) | 1200 |

| number of blades (pcs) | 12 |

| Max. cutting size (mm) | 3000*1600*450 |

| Workbench size (mm) | 2500*1800 |

| Weight (t) | 10 |

| Max. cutting depth (mm) | 450 |

| Main motor power (kw) | 55 |

Production Process:

1. Put the machine on the prepared ground.

2. Put several pieces of wood as thick as 50mm on the worktable to prevent blades from cutting into the worktable.

3. Install water pipe.

4. Blade installation: Open blade cover, unscrew 8 retaining bolts and position bolts with a dedicated spanner, loosen auxiliary spindle (shaft), put on blades and clamping plates as per intended stone size (thickness), align oil hole of the auxiliary spindle to air hole according to the arrow direction on auxiliary spindle and box, have them fixed with bolts, close blade cover.

5. Check transmission fluids of the spindle box, auxiliary spindle box, trolley track, and lifting parts.

6. Connect control cabinet power.

After Sales Service:

We provide skilled and rich experience technicians for installation and after-sale service.

| Pre-Sales Service * Inquiry and consulting support. * Configure the best machine line according to customer condition * View our Factory. | After-Sales Service * Training how to install the machine, training how to use the machine. * Engineers available to service machinery overseas. * Lifetime technology maintenance in free and spare parts supply. Related Products |

Packaging&Shipping:

The machine will be consolidated tightly and safely within the container and delivered by sea or railway, we offer fast delivery and prompt reaction.

Company profile:

Quanzhou Dafon Machinery, located in Shuitou Town, is a professional stone machinery enterprise integrating design, manufacturing, and sales. Mainly produce curbstone assembly line equipment, Infrared bridge cutter, automatic edge cutting machine, Infrared middle bridge cutter, single arm block cutter, bridge block cutter, mining machine, and other types of stone machinery.

The company has advanced mechanical processing equipment, standardized workshops, a strong technical force, efficient research and development team, and rich experience in stone machinery production, which make the company continue to be at the forefront of stone machinery. Relying on the advantages of strong industrial clusters, the company provides customers with free one-stop solutions for the stone industry (granite), including mining planning guidance, technical consultation, technical output, equipment procurement, processing, construction guidance, etc. As long as you invest in the stone industry, we provide you with a series of professional services.

FAQ:

Q1: What is your competitiveness?

A: We can provide a one-stop shopping service. Our machine has a good price with the best quality. Each machine has its long lifetime, high production capacity, and accuracy. Also, we could appoint our engineer to come overseas to help the customer if the machine got a problem.

Q2: When do you ship my order?

A: Normally 20-30 days after receiving final payment, but it can be negotiated if customers need it urgently.

Q3: How about the quality guarantee period?

A: one year for machine parts, 6 months for the electronic parts

Q4: What's your advantage? Why did we choose you?

A:1)Rich experience in stone machine production and R&D. We have the most professional techniques and team. More advantages in price

2) Great production capacity and Sustainable Supply. According to customer requirements, We support the customized include package.

3)We use 100% new materials and the best production process, in consequence, our defective rate is lower than 0.01%

Q5: How about the delivery of goods to our country?

A: For urgent or small orders with lightweight, the express courier will be preferable to save time and trouble of goods clearance(door to door); As for bulk orders or machinery orders, by sea(maritime way) is recommended for lower shipping cost. But it is taking a long time

Our Contact